How does a foil stamping machine work?

In the field of printing and design, hot stamping machines are like magicians, turning ordinary surfaces into dazzling works of art. From wedding invitations to luxury packaging, foils are attractive enough to catch the eye and add a touch of sophistication to any project. But how exactly does a foil stamping machine work its magic? Let’s uncover the secrets behind this fascinating process.

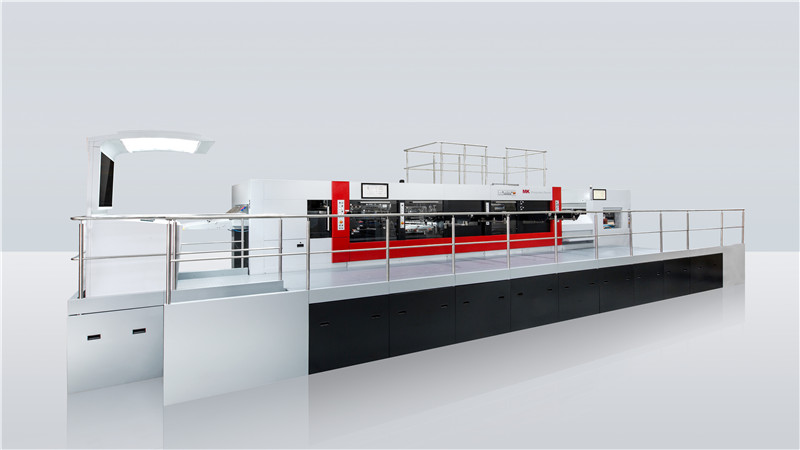

Analysis of hot stamping machine

A foil stamping machine is a precision piece of equipment designed to precisely apply metal or pigment foil to a variety of substrates. While the size and complexity of different models may vary, the basic components remain consistent across the board:

Heated Mold or Plate: The heart of every foil stamping machine is the heated mold or plate. The component is made of metal with the desired design or pattern that will be transferred to the substrate. The mold is heated to a specific temperature to ensure optimal adhesion of the foil during the foil stamping process.

Foil roll: A foil roll is a thin metal or colored material wrapped on a spool. Aluminum foil rolls are available in a variety of colors, finishes, and effects and serve as a medium for transferring designs to substrates.

Substrate: The substrate refers to the surface on which the foil is transferred. Common substrates include paper, cardboard, plastic, leather, and fabric, each providing a unique canvas for foil decoration. If necessary, contact the hot stamping machine manufacturer.

Unveiling the hot stamping process

The foil stamping process unfolds through a series of carefully planned steps, each helping to create a stunning finished product:

Preparation: The foil stamping process begins with preparing the mold and substrate for heating. The mold is heated to the precise temperature required for foil bonding while the substrate is placed beneath the mold, ready to receive the foil.

Foil Application: Once the mold reaches optimal temperature, the foil roller is advanced, bringing a new layer of foil into contact with the heated mold and substrate. When pressure is applied, the foil adheres to the substrate, reflecting the intricate design engraved on the mold.

Cooling and Removal: Once the foiling process is complete, allow the substrate to cool to ensure the foil is firmly adhered to the surface. Once cooled, excess foil will be removed, revealing clear, detailed foil impressions that sparkle in the light. Contact Masterwork to get the lowest hot stamping machine prices.

Foil Stamping Machine Versatility and Applications

Hot stamping machines offer unparalleled versatility and are suitable for numerous applications across a variety of industries:

Packaging: Aluminum foil adds a touch of elegance and luxury to product packaging, making it ideal for cosmetics, chocolate, beverages, and high-end consumer goods.

Stationery and Invitations: Wedding invitations, greeting cards, and stationery benefit from the sophisticated finish that foil provides, setting the tone for unforgettable events and celebrations.

Branding and Marketing Materials: Business cards, brochures, and promotional materials stand out by adding decorative elements, increasing brand awareness, and leaving a lasting impression on recipients.

In summary

In the world of printing and design, foil stamping machines reign supreme as masters of glamor and sophistication. These machines transform ordinary surfaces into extraordinary works of art that continue to inspire creativity and captivate audiences around the world. Whether decorating packaging, invitations, or promotional materials, the captivating appeal of foil always leaves a lasting impression.